FLASKER

FLASKER è un gesso duro con ottime caratteristiche di lavorabilità, che, insieme ad un grado di durezza intermedio, ne fanno il prodotto d’elezione per la realizzazione di stampi e muffole.

Il tempo di lavorazione del prodotto è calibrato per migliorare l’efficienza e la produttività del vostro laboratorio; La muffola è pronta per l’iniezione.

FLASKER es una tiza dura con excelentes características de maquinabilidad, que unidas a un grado intermedio de dureza, la convierten en el producto de elección para la elaboración de moldes y moldes en muflas.

El tiempo de procesamiento del producto está calibrado para mejorar la eficiencia y productividad de su laboratorio; La mufla está lista para la inyección.

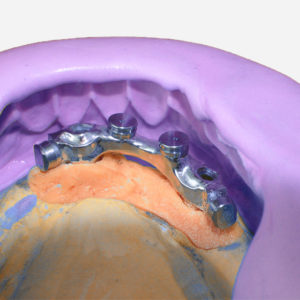

FLASKER is a hard chalk with excellent machinability characteristics, which, together with an intermediate degree of hardness, make it the product of choice for the production of moulds and moulds in muffles.

The processing time of the product is calibrated to improve the efficiency and productivity of your laboratory; the muffle is ready for the injection .

operating instructions

Take the amount of powder needed to make the mold/ counter mold, weighing it carefully. Respecting the mixing ratio, take the amount of demineralized water needed for the dough, using a graduated cylinder or, more simply, weighing the water directly into the bowl. Gently pour the powder into the bowl containing the water (not vice versa) and wait 15 seconds for the powder to be soaked by the liquid. Using a metal spatula, premix manually gently for a few seconds, so that all the dust is wet. Then mix Then mix vigorously for the indicated time.

Take the mixture in small portions with the spatula and pour it slowly into the footprint (placed on top of a vibrator adjusted to a minimum), making it flow from a distal end. This avoids the possibility of incorporating air bubbles in the final model. As soon as the footprint is filled stop the vibration, then wait for the indicated time before removing the model.

FLASKER è un gesso duro con ottime caratteristiche di lavorabilità, che, insieme ad un grado di durezza intermedio, ne fanno il prodotto d’elezione per la realizzazione di stampi e muffole.

Il tempo di lavorazione del prodotto è calibrato per migliorare l’efficienza e la produttività del vostro laboratorio; La muffola è pronta per l’iniezione.

FLASKER es una tiza dura con excelentes características de maquinabilidad, que unidas a un grado intermedio de dureza, la convierten en el producto de elección para la elaboración de moldes y moldes en muflas.

El tiempo de procesamiento del producto está calibrado para mejorar la eficiencia y productividad de su laboratorio; La mufla está lista para la inyección.

FLASKER is a hard chalk with excellent machinability characteristics, which, together with an intermediate degree of hardness, make it the product of choice for the production of moulds and moulds in muffles.

The processing time of the product is calibrated to improve the efficiency and productivity of your laboratory; the muffle is ready for the injection .

operating instructions

Take the amount of powder needed to make the mold/ counter mold, weighing it carefully. Respecting the mixing ratio, take the amount of demineralized water needed for the dough, using a graduated cylinder or, more simply, weighing the water directly into the bowl. Gently pour the powder into the bowl containing the water (not vice versa) and wait 15 seconds for the powder to be soaked by the liquid. Using a metal spatula, premix manually gently for a few seconds, so that all the dust is wet. Then mix Then mix vigorously for the indicated time.

Take the mixture in small portions with the spatula and pour it slowly into the footprint (placed on top of a vibrator adjusted to a minimum), making it flow from a distal end. This avoids the possibility of incorporating air bubbles in the final model. As soon as the footprint is filled stop the vibration, then wait for the indicated time before removing the model.

Immagini packaging/ Packaging Pictures

Caratteristiche Tecniche/Technical Features

(normativa EN ISO 6873:2013)

Rapporto miscelazione- Mixing ratio

(acqua : polvere)

38 - 40 ml : 100 g

Tempo miscelazione- Mixing time

(manuale)

60”

Tempo lavorabilità / presa- Workability / gripping time

5' / 9'-11'

Espansione lineare presa- Linear expansion socket

(2 h)

0,14 %

Resistenza compressione- Compressive strength

(1 h - 24 h)

24 MPa - 37 MPa

Packaging & Colorazioni/Packaging & colours

| bianco/white | avorio/ivory | |

|---|---|---|

| Sacco 25 Kg | GK13RW25S | GK13RI25S |

| bianco/white | avorio/ivory | |

|---|---|---|

| Cartone 20 Kg | GK13RW20C | GK13RWI20C |

it

it  English

English